Printers and converters depend on MECA’s range of process rolls

Printers and converters depend on MECA’s range of process rolls

Process rolls for packaging form the asset base that printers and converters depend on for operational quality and efficiency. MECA, an industry leader in the design and production of premium process rolls for packaging, engineers solutions that increase throughput and reduce downtime for maximum profitability.

MECA’s expertise in design and manufacturing of process rolls for packaging, that range from standard idlers to advanced vacuum tension rolls (VTR), gives customers the ability to simplify their ordering process with a single supplier.

Process rolls for packaging increase manufacturing versatility

Our engineering and production teams are committed to delivering the finest quality process rolls for packaging on the market. Manufacturers of high-performance packaging materials require a wide range of our products for their operations, and our customers depend on excellence with each order.

Visit https://www.mecagb.com/ for a complete list of our products and services. But while you’re here, below is a brief description of some of our most commonly requested products:

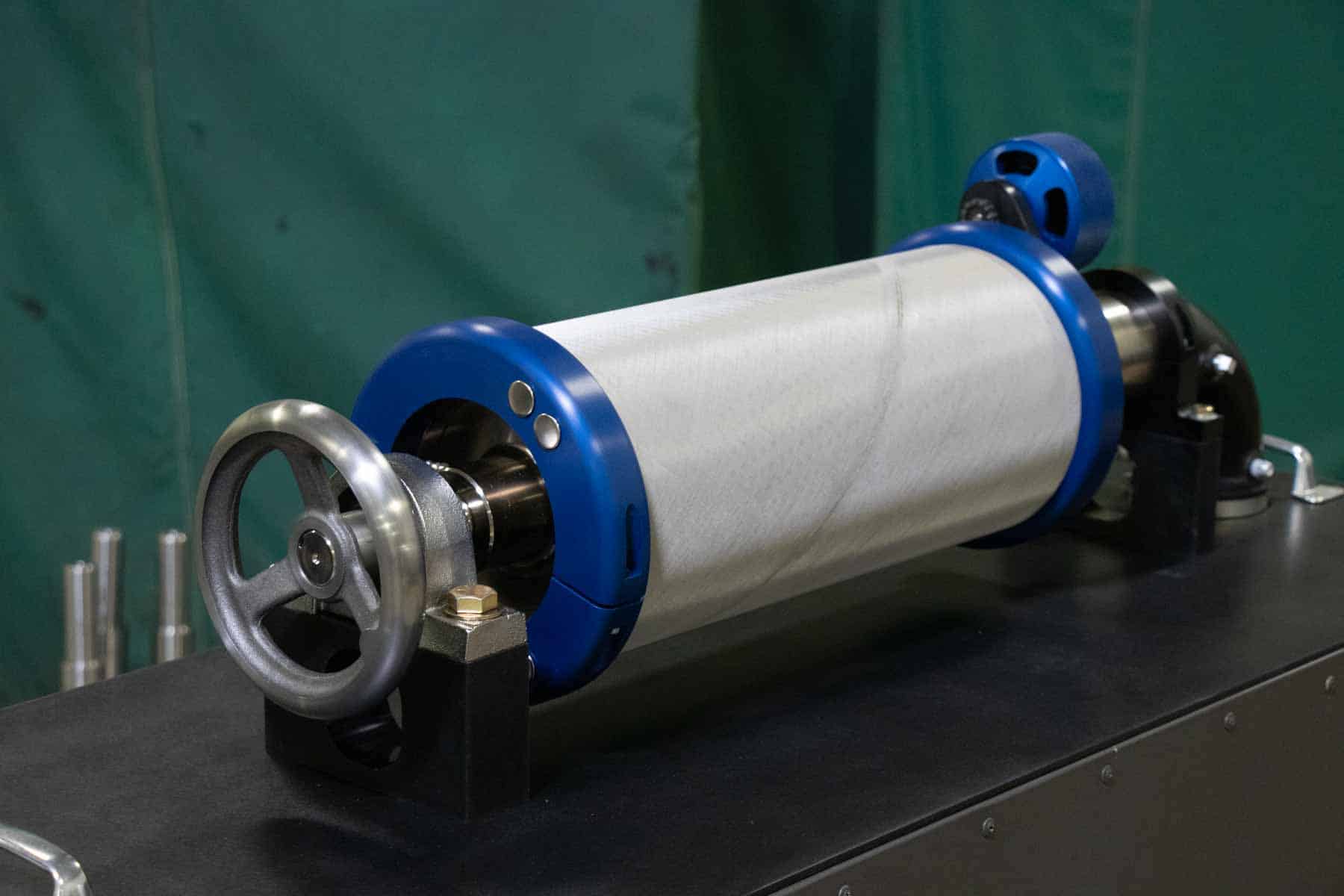

Vacuum tension rolls (VTR) – MECA’s vacuum tension rolls provide high-quality drive and tension control on a substrate when single-sided web contact is required.

Heat transfer rolls – Our heating and cooling rolls enable your processes to achieve heat transfer benefits while managing energy use, fluid flow and pressure loss.

Engraved rolls – Precision mechanically engraved rolls are the products we mastered first when our company opened nearly 40 years ago. We can fulfill even the most stringent cell requirements, building new rolls as well as reconditioning old ones.

Mandrels – We engineer our carbon fiber mandrels specifically for flexographic printing presses. Available with conventional air actuation or internal piping, these mandrels are lightweight and are appropriate as base mandrels to mount all MECA print sleeves.

Sleeves – MECA produces a variety of sleeves that retain tight tolerances while running at high speeds. For example, MECA is the only certified VSOP sleeve manufacturer in North America. Our variable speed offset printing (VSOP) plate and blanket sleeves are made with carbon fiber to maintain dimensional stability.

Anilox sleeves – We solved a problem common with anilox sleeves with our “Smart Memory” cushion layer which returns the sleeve to its tight original fit with the mandrel when air pressure is removed, all while maintaining tolerances unmatched in the industry.

Idler rolls – These basic, but important, assets support the line and keep the web moving between drive rollers.

For more information about process rolls for packaging or MECA’s design and manufacturing capabilities, please call Pete Eggen (920) 338-0138, or visit https://www.mecagb.com/.

About MECA

MECA is a premier manufacturer of precision rolls for the printing and web handling industries. MECA specializes in flexographic print sleeves, heat transfer rolls, carry rolls, mandrels, coating rolls and vacuum rolls. As part of the Precision Roll Solutions family, MECA helps the world’s leading manufacturers leverage texture and other process variables to make their products more effective and enhance their impact in the marketplace.

View the original article on process rolls for packaging here.