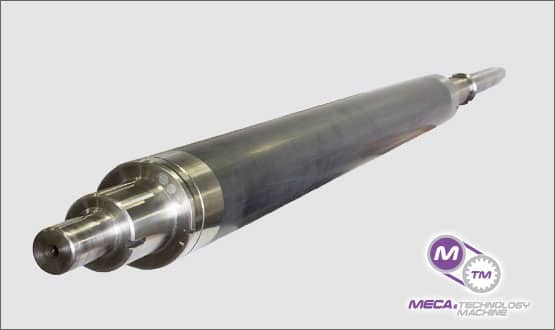

Light-Weight Product Enables High-Quality Printing at Faster Speeds

GREEN BAY, Wisconsin – Flexographic printers are relying on carbon fiber bridge mandrels produced by MECA & Technology Machine, Inc. for use on today’s high-speed presses. Light-weight, carbon fiber bridge mandrels offer superior performance characteristics without sacrificing stiffness at the point of impression. In addition, press manufacturers generally can use smaller drive motors to achieve the desired results.

“Carbon fiber offers enhanced vibration absorption properties that come in handy at high press speeds,” said Mick Karchinski, Vice President of Sales. “They have become more affordable over the past several years and provide an attractive return on investment when paired with the ability to run at faster speeds.”

Carbon Fiber Bridge Mandrels Support High-Speed Setups

Carbon fiber bridge mandrels offer maximum stiffness while withstanding the exceptional stresses that presses generate when running at tight tolerances and high speeds. Bridge mandrels are used to build a larger print diameter while supporting a sleeve during printing. They are commonly used in tandem with thin sleeves when the press operator expects to keep jobs mounted or have several repeats within a few gear teeth of each other.

“Traditional sleeves lack the stiffness necessary for high-quality impressions at higher press speeds,” Karchinski said. “That’s where carbon fiber bridge mandrels becomes a cost-effective addition to the press setup.”

About MECA & Technology Machine

MECA & Technology Machine Inc. is an innovative gear manufacturer and engineering provider of tight-tolerance machined components, such as carbon fiber, steel, stainless steel and aluminum cylinders, gears, composite flexographic plate and bridge sleeves, aluminum and carbon fiber anilox sleeves, and mechanically engraved rolls for the industrial, flexographic, coating and converting industries. The company employs more than 50 people at its facilities in Green Bay, Wisconsin.

For more information about MECA & Technology Machine’s printing press sleeve capabilities, call Mick Karchinski, Vice President of Sales, at (920) 336-7382, or visit https://www.mecagb.com/.