Powder-coated metal enclosures are among the beneficiaries of new facilities

Powder-coated metal enclosures are among the beneficiaries of new facilities

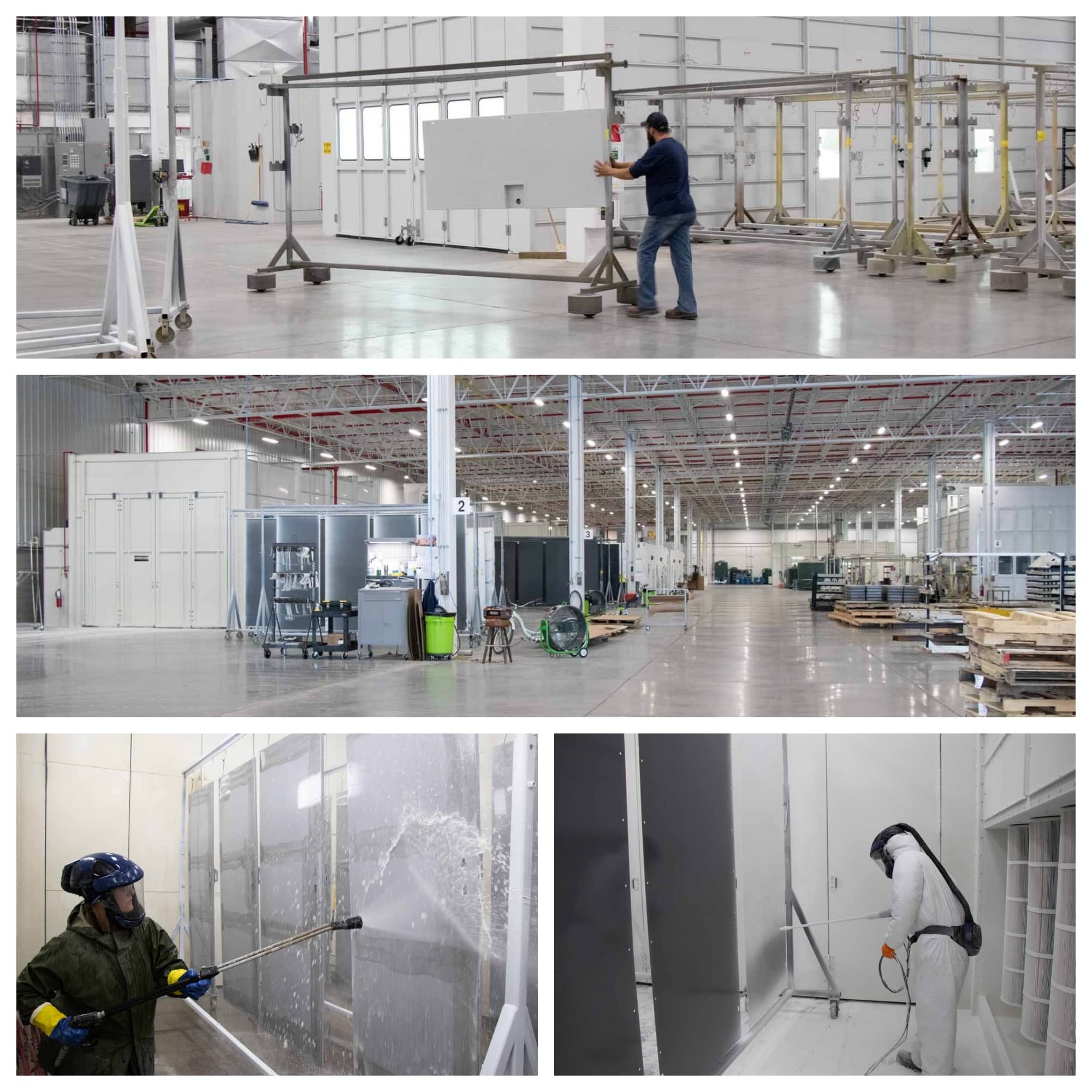

Robinson has increased its ability to pre-treat, paint and apply powder coatings to products ranging from small parts to large metal enclosures and tanks at its De Pere, Wisconsin, manufacturing campus. The investment covers nearly 90,000 square feet of production space.

The ability to deliver orders as large as powder-coated metal enclosures places Robinson on a higher tier in terms of on-site paint and powder coating facilities among metal fabrication companies.

“We need a big envelope in order to accommodate our larger projects,” explains Bob Whitefield, paint and coatings manager for Robinson. “Fuel tanks, water tanks, and powder-coated metal enclosures all fall outside the size capabilities of most of our competitors. This completes a key aspect in our efforts to monitor quality control and serve as a single-source solutions provider for our customers.”

Robinson’s expanded facilities feature two liquid spray booths, both measuring 60 feet in length x 20 feet wide. One booth is 14 feet tall and the other 17 feet tall. The powder coating line includes a pair of booths that are 35 feet long, 16 feet wide and 15 feet high. Two powder coat ovens complete the process, both measuring 30 feet long, 12 feet wide and 12 feet high.

Pre-treatment options enhance paint and powder coating processes

Robinson’s pre-treatment capabilities include a blasting booth measuring 60 feet long, 20 feet wide and 14 feet tall that will come on line by the end of August. The blasting process, using aluminum oxide, removes dust or mill residue from metal prior to the application of paint or powder. It also enables Robinson technicians to apply an anchor profile to materials such as sheet metal for enhanced coating adhesion.

Two pre-treatment wash pools in the facility are capable of using iron phosphate or zirconium to prepare and protect surfaces for coating. These solutions apply a protective barrier that prevents corrosion and oxidation of the metal.

“Zirconium is a relatively new technology in the world of pre-treatment,” Whitefield says. “It provides exceptional protection and is environmentally friendly compared to using a large amount of phosphate.”

About Robinson, Inc.

Robinson, Inc., is a single-source metal fabrication solutions provider based in De Pere, Wisconsin. Robinson offers manufacturing and design expertise in fabrication and machine; pipe and vessel; custom enclosures; product handling concepts; and portable fuel solutions. The company employs more than 450 people at three locations comprising 500,000 square feet of manufacturing space.

For more information about Robinson’s paint or coatings capabilities or to request a quote, please call (920) 494-7411, or visit https://www.robinsoninc.com.

View the original article on powder-coated metal enclosures here.

Tags: laser cutting