Industrial Engraving develops custom patterns for a wide range of converters

Industrial Engraving develops custom patterns for a wide range of converters

Embossing roller design is an important aspect of the converting process that can make the difference between exceptional product performance and just another consumer option. Consumer product manufacturers rely on embossing roller design from Industrial Engraving to minimize raw material consumption and maximize profits.

As a North American leader in embossing roller design, Industrial Engraving’s engineering team is experienced in assessing customer needs and developing effective solutions for production objectives. Pattern differentiation is a key performance characteristic, particularly for trash bag embossers with an eye toward superior dart strength.

Your operations group can leverage the expertise of our engineering and production specialists to refine pattern nuances that translate into positive impact on your web. Embossing roller design benefits manufacturing processes for a wide range of commonly used items such as:

- Garbage bags and agricultural film

- Light personal protective equipment (gloves and aprons)

- Barrier films for the medical industry (gowns, drapes and dental bibs)

- Vacuum seal/food service bags or sheets

- Packaging film embossed image or tear strip

- Wipes (film bonded to tissue for paper towels)

- Hygienic film for nonwovens (diapers, feminine hygiene)

- Table covers (film and film/tissue)

Our team also is producing an increasing number of embossing roller designs for thin sheets of metal. Custom dimple patterns enhance rigidity and contribute to heat-shielding performance.

Test runs ensure an embossing roller design hits the target

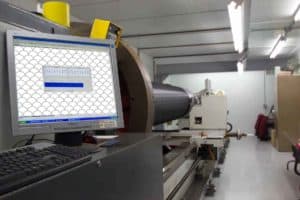

We understand investing in new embossing rolls is a significant financial commitment. That’s why we often test an embossing roller design on ebonite first to ensure the customized pattern performs as expected with the desired raw material.

Laser-engraving an ebonite roll for trial purposes saves money compared to using a steel roll. If the trial is successful, we then transfer the pattern to a steel roll to take advantage of its longer life span than the hard plastic of ebonite.

Our product line includes simple idler rollers that feed web through a line to nip rolls, heat transfer rolls, and heavy-duty rolls with intricate patterns. Put our engineering resources to work on the embossing roller design for your application.

About Industrial Engraving

Industrial Engraving offers custom embossing rolls and embossing machines for customers operating in a variety of paper, tissue, foil, film and nonwoven markets. Industrial Engraving’s comprehensive services include roll refurbishment, pattern development, and design and production of embossing and calendering equipment. As part of the Precision Roll Solutions family we help the world’s leading manufacturers leverage texture and other process variables to make their products more effective and enhance their impact in the marketplace.

For more information about Industrial Engraving’s design and manufacturing capabilities, please call 920-865-7304, or visit https://www.industrial-engraving.com/.