American Custom Converting fulfills precise customer requirements

American Custom Converting fulfills precise customer requirements

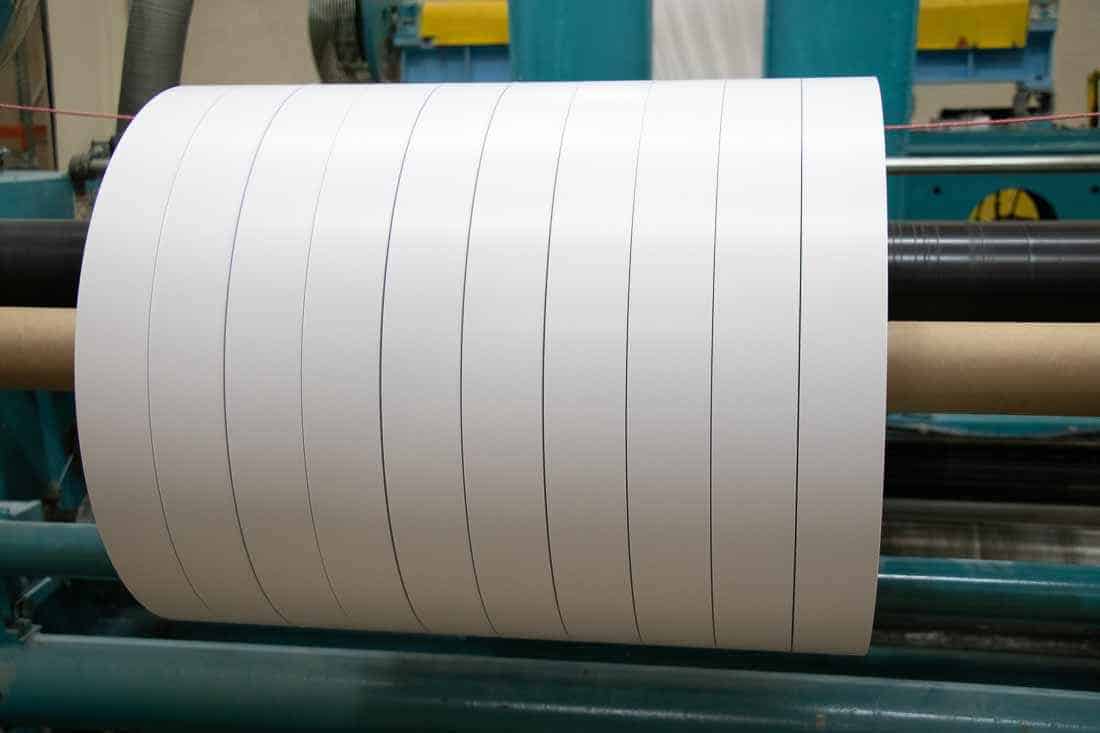

The process of cutting large parent rolls down to more manageable sizes brings with it a variety of challenges depending on the substrate and end product use. American Custom Converting’s plant in Green Bay, Wisconsin, features multiple machines that deliver custom slitting and rewinding operations for a wide range of applications.

ACC’s custom slitting operations can handle widths up to 135 inches with the capability of slitting and rewinding a wide range of materials:

- Single ply

- Multi-ply

- Nonwoven materials

- Paper

- Tissue

- Film

“The reality is there is no such thing as a single custom slitting machine that can fulfill every need,” says Mark Kyles, managing member of sales at American Custom Converting. “Our customers come to us with a variety of materials and requirements, which is why we have invested in multiple machines capable of meeting most requests.”

Custom slitting services create opportunities for efficiency

ACC’s services provide a solid return on investment for companies who benefit from outsourcing this part of their operations. Machines often must be built or modified to handle variations in materials for consistently high-quality results.

ACC, also a leader among nonwoven folding converters, has the versatility to deliver single-run custom slitting orders along with repeat business. The company’s engineering team has a track record of successfully developing machines that accomplish orders ranging from unique to mainstream.

“This is what we do, and that is not necessarily a core competency for many of our customers,” Kyles says. “In fact, most companies have no desire to make the type of capital investment required to meet the variety of requirements on custom slitting that our teams are able to deliver.”

About American Custom Converting

American Custom Converting is a Green Bay, Wisconsin-based converter of paper, tissue, nonwovens and other substrates, as well as a provider of hot and cold lamination services, folding and packaging, aqueous coating, complete product finishing, and contract manufacturing. ACC teams adhere to Current Good Manufacturing Practices (CGMPs), supported by a dedicated Quality Assurance Manager, and are dedicated to adding value with integrity for every customer.

For more information on American Custom Converting or to request a quote, go to http://www.acconverting.com/ or call 920-494-3258.

View original article on custom slitting here.