Welding, machining, coatings combine to meet OEM specifications

Welding, machining, coatings combine to meet OEM specifications

Aluminum fabrication comprises a subset of service offerings that Titletown Manufacturing provides in delivering high-quality components for original equipment manufacturers (OEMs). The strength and lightweight characteristics of aluminum make it the ideal material for a wide range of applications.

Titletown Manufacturing completes aluminum fabrication using a variety of alloys depending on customer requirements, including 6061 and 7075. The 7075 alloy is considered aircraft-grade because it has a higher yield strength, enabling it to withstand more stress without deformation.

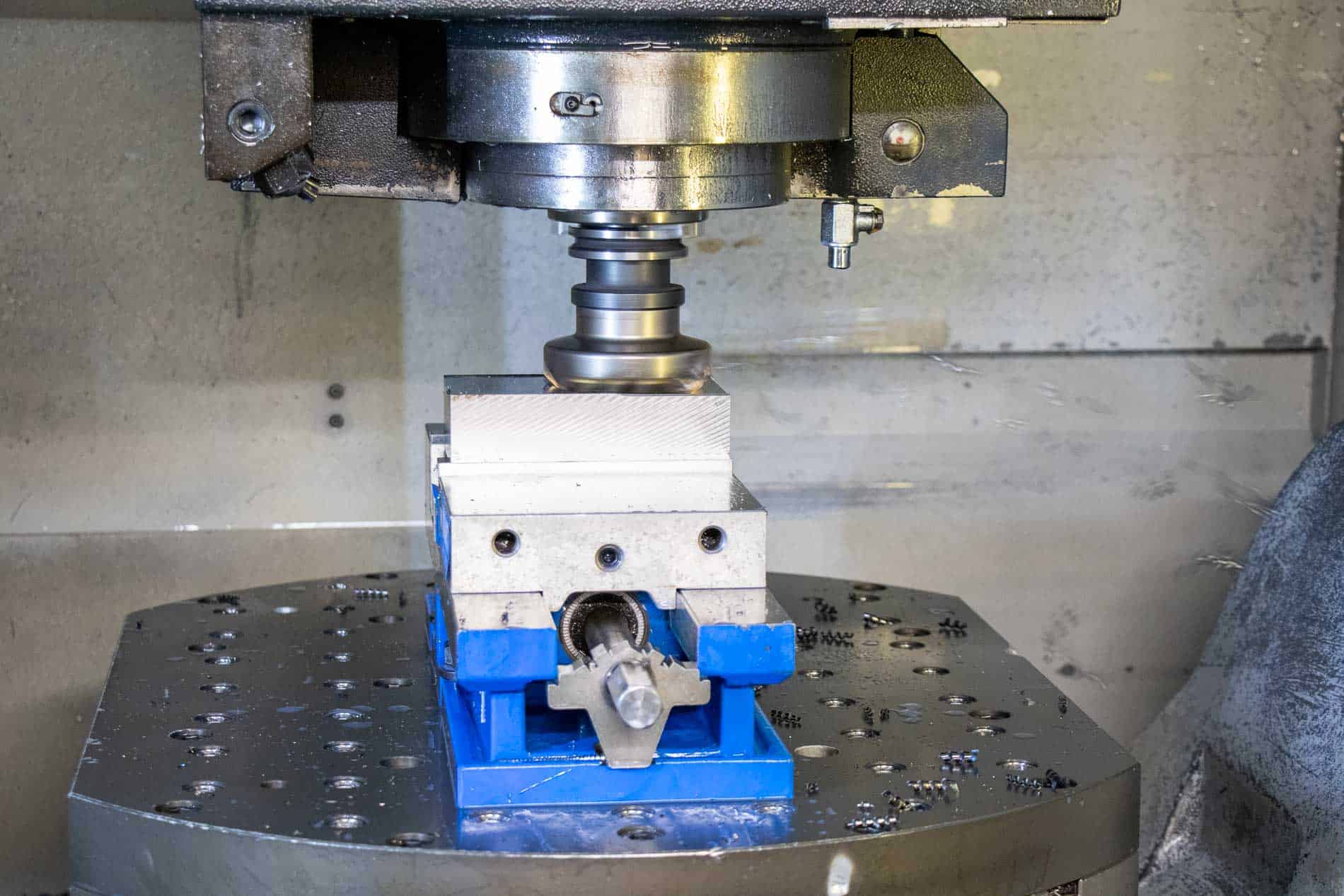

Our custom metal milling expertise is a crucial step in the aluminum fabrication process. Aluminum comes to us in an extruded state, from which we machine it into desired sizes for use in creating components used in larger projects.

Aluminum fabrication requires multiple handling steps

The overall aluminum fabrication process often involves several steps on the way to delivering the final component. We build solids in a variety of shapes, including round, square and rectangular bars, as well as containers such as ink chambers and tubing. Sheets of diamond-plate aluminum, such as what you would find on the exterior of trailers and other active container applications because it is less prone to denting.

Titletown Manufacturing teams often work with aluminum that carries a T6 modifier, which designates the alloy has been subjected to a solution heat treatment followed by quenching, cooling and aging. This process provides for better flow during subsequent welding or bending steps, making it easier for our specialists to avoid cracks and gaps when joining parts together.

Specific coatings comprise the final steps of the aluminum fabrication process. Aluminum anodizing is a common process used to increase the thickness of the oxide layer that forms naturally when any aluminum surface is exposed to air, while nickel plating provides last-step protection.

About Titletown Manufacturing LLC

Titletown Manufacturing LLC is a trusted metal machining and fabrication shop with over 60 years of experience in CNC machining, welding, grinding, assembly and reverse engineering for a wide range of industrial customers throughout the region. The company employs more than 30 people at its facility at 817 Marquis Way in Green Bay, Wisconsin.

For more information on Titletown Manufacturing or to request a quote, please go to https://titletownmfg.com or call 920-435-9074.