MECA & Technology Machine Boosts Carbon Fiber Bridge and Anilox Sleeve Capabilities

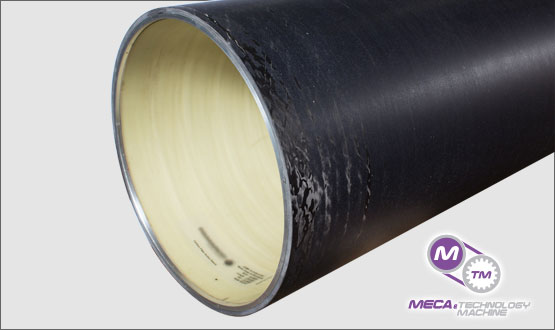

GREEN BAY, Wis. – MECA & Technology Machine, Inc. has solidified its status as an industry leader in the design and manufacture of carbon fiber bridge sleeves for customers throughout North America.

The company’s recent delivery of a carbon fiber anilox sleeve that is believed to be the largest in the world illustrates its ability to custom-design anilox and bridge sleeves for a variety of press sizes.

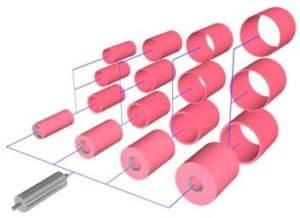

“Carbon fiber’s exceptional vibration absorption properties enhance the performance of today’s high-speed presses,” stated Mick Karchinski, Vice President of Sales.

MECA & Technology Machine designs its carbon fiber bridge and anilox sleeves to withstand the extreme stresses of presses running at tight tolerances and high speeds. The carbon fiber structure is designed for maximum stiffness and peak performance.

“Carbon fiber offers the strength of steel with dramatic reduction in weight,” Karchinski said. “This is an especially important characteristic when dealing with large-scale bridge sleeves, where weight can be a limiting factor.”

The combination of vibration absorption and significant weight reduction generates less inertia compared to cylinders made of steel. In addition, carbon fiber bridge and anilox sleeves offer the ability to use smaller drive motors along with faster stopping capabilities than their steel counterparts.

“The decrease in carbon fiber raw material costs during the past few years is making it easier for our customers to invest in this high-performing material,” Karchinski said. “The vibration-absorption properties of carbon fiber sleeves also generally lead to reduced maintenance costs.”

MECA & Technology Machine employs approximately 50 people at its Green Bay, Wis., facilities. For more information, call Mick Karchinski at (920) 336-7382.

To see the full article, click here.