Specialized Saw Sharpening Equipment for Sale from the Experts at Thorvie International

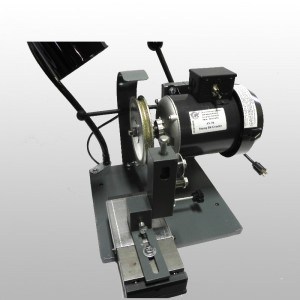

Adding the mason drill bit fixture to the Thorvie International AV-40 professional grinder can provide an additional revenue stream for your home-based sharpening business. Drilling into masonry takes a toll on drill bits, and saw sharpening equipment for sale from Thorvie International such as the AV-40 provides the adaptability you need to get the job done.

Adding the mason drill bit fixture to the Thorvie International AV-40 professional grinder can provide an additional revenue stream for your home-based sharpening business. Drilling into masonry takes a toll on drill bits, and saw sharpening equipment for sale from Thorvie International such as the AV-40 provides the adaptability you need to get the job done.

“Many of your competitors overlook the untapped opportunity that exists with sharpening mason drill bits,” notes Rick Shefchik, Sales Manager at Thorvie International. “You can put a lot of extra money in your pockets providing this specialized sharpening service.”

All Thorvie International products provide high-quality sharpening capabilities that differentiate you from the competition and turn customers into repeat customers. The AV-40 and all Thorvie International products come with written instructions and a training DVD.

“Our business focuses on helping entrepreneurs create a profitable home-based business,” Shefchik says. “Thorvie’s success depends on your success, and we’ll do everything in our power to help you attain it. That includes assistance with everything from pre-launch planning to business functions such as invoicing and sales lead information.”

Rick’s Tip

Mason drill bit sharpening on the AV-40 Saw Blade Sharpening Machine is quite simple, fast and very profitable. Sharpening mason drill bits features a lot of the same principles as top grinding a saw blade. The one thing you need to make sure of is that the center point of the mason bit remains centered. When used properly, the Thorvie Mason Drill Bit Sharpening Fixture will center the tip every time.

First, set up and sharpen one of the two flutes of the mason bit using a diamond grinding wheel. Once you have it lined up correctly, adjust your motor in or out until there is a medium to light grind, depending on how rounded the cutting edge of the carbide is. Then tighten down the motor slide lock knob on the AV-40 so the motor will not travel left or right. When you grind the first flute, sharpen that flute until the grinding wheel barely makes contact with the mason bit and you can barely hear the sound of the grind.

Do not loosen or rotate the drill bit to sharpen the next flute until you set the built-in stop arm. Set the stop arm against the mason bit tip and lock it in position, then loosen by rotating the bit 180 degrees and lock it in place to sharpen the second flute. It is very important that you never move your motor in or out, or change the initial fixture setup. Move the stop arm clear from the mason bit and grind the second flute until the grinding wheel barely makes contact with the carbide tip and you you barely hear the sound of the grind. Your mason drill bit will be sharp, with the tip perfectly centered every time.

For more information on the mason drill bit fixture, circular saw blade sharpeners and other saw sharpening equipment for sale, call Thorvie International at 866-497-0572 or visit the website at thorvie.com.

View original post on saw sharpening equipment for sale here.